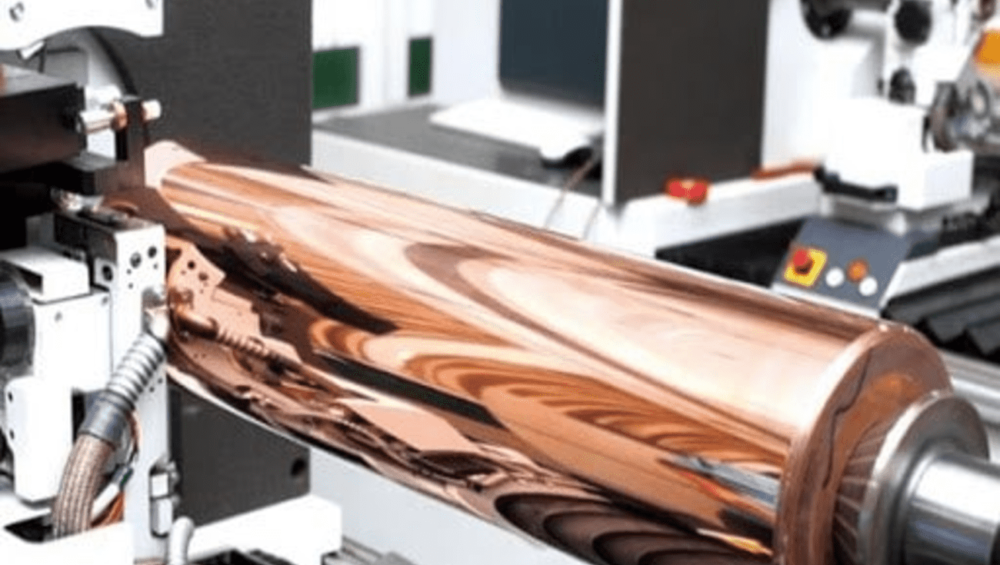

Electroplating offers many benefits for different purposes. Copper plating in UAE is done by many companies for taking the advantage of the metal coating on other surfaces or metals. The metal offers high conductance and corrosion resistance, and hence, is ideal for many applications that shall be discussed in this article.

Copper is a unique metal and electroplating companies in UAE prefer this coating for the compatibility it shows with the other metals and alloys.

Quality Improvement with Copper Electroplating

Copper electroplating in UAE is done with other metals, or exclusively in the plating process. If the properties of a metal are required to be changed, the process of electrolysis can do the needful. Taking the example of Nickel, the high resistance from wearing of the metal can be enhanced with the additive anti-corrosive features that can be provided only by copper electroplating. The resultant will make the surface highly durable.

Key benefits of copper coating

Copper is a soft malleable metal that makes it an ideal option for electroplating purposes. It is naturally adhesive that doesn’t separate it from the metals even on bending or reforming. Copper electroplating increases the corrosive resistance and results in the thick layer building that can act as a resistance for heating. It can even withstand the high-temperature and lubricant passage.

The metal coating companies in Dubai prefer copper for its supreme conductivity that makes it an underplating object for a nickel or tin plating. It can even give metallic properties to non-metallic materials, like plastics. The introduction of the cyanide solution to the electroplating bath can give a highly sturdy adhesion to the copper plating. However, being a highly toxic substance, cyanide requires great care to be used in the electroplating process in UAE.

Properties of Copper Metal

Copper is the most important material for electroplating. Here is a close look at the properties which have made copper obtain a strong impact in the electroplating industry:

Conduction: Copper is the 2nd most conductive metal and is way cheaper than the first one in this category, i.e., silver. Copper is the best choice for industrial and commercial usage for electroplating. This is the reason that the metal coating companies prefer this metal over the other options available.

Corrosion-resistance: Copper is again not the supreme metal for corrosion resistance but when it is combined with other highly corrosive-resistant metals, like Nickel; the results for anti-corrosive properties are supreme.

Adhesion: Copper creates an even and smooth protective layer on the metals during the electroplating process. It is a perfect under or top-coat with an intact layer providing all the properties of the metal. The copper layer stays intact with its adhesive properties and the final product remains layered for a longer time.

Cost-effective: Copper is not an expensive metal. It is way cheaper than precious metals like gold and silver. Copper plating in UAE is recommended to get different qualities at a cheaper price than the use of noble metals.

Conclusion

Classic Metals Sheet Factory LLC is one of the renowned metal coating companies in Dubai working for small to commercial level electroplating. The process of electroplating requires the perfect ways to make every surface and metal worthwhile. Our company works professionally with the core values of high commitment, integrity, unity, excellence, and passion for the work. We work for various projects of electroplating in UAE with a wider scope of our services for the commercial sector. Our fine copper plating in UAE is done for giving a dull reddish tone to the various surfaces with a shiny or a matte look, depending on the requirements. Feel free to contact our experts and they will guide you towards the electroplating processes we follow along with the suggestions for your work. We work in a dedicated way and offer electroplating in Dubai and UAE at cost-efficient rates.