Welcome To

Classic

Metal Coating

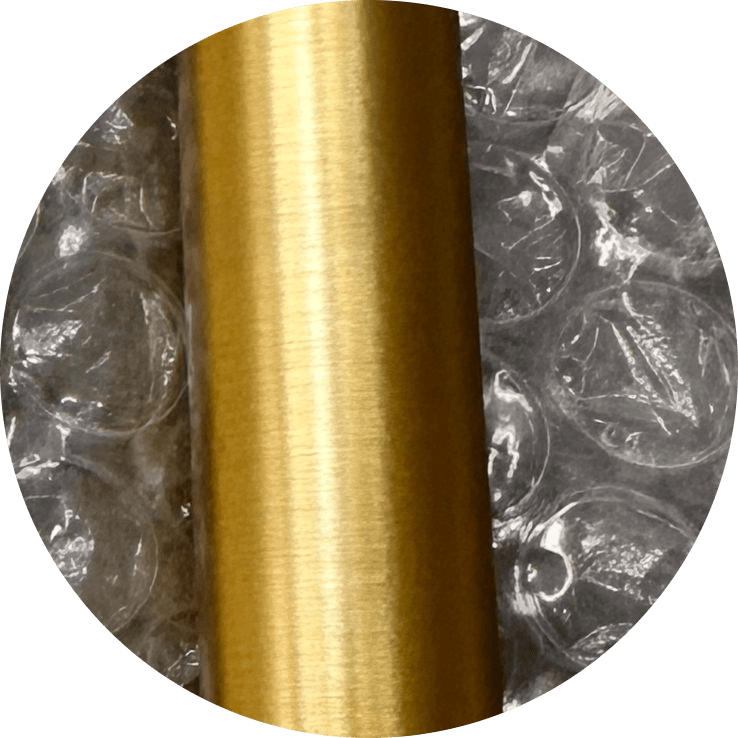

Gold / Silver

Nickel and Chrome

Antique Finishes

Your Premier Destination for PVD Coating, Electroplating & Metal Finishes

From functional to fabulous — transform your metal surfaces with style

Welcome to Classic Metal Coating, one of the most trusted names in metal coating in UAE, where craftsmanship meets cutting-edge technology. With over 19 years of industry experience, we’ve established ourselves as a leading force among metal coating companies in Sharjah, Abu Dhabi, Dubai, and whole UAE, known for precision, durability, and aesthetics in every finish. Whether you’re an architect, interior designer, contractor, or business owner, we provide comprehensive metal fabrication and electroplating in UAE that bring your vision to life—on time and with unmatched quality.

Are you in search of metal coating in Dubai? Call Us Right Away!

Our Specialities

A Legacy of Quality Since 2006

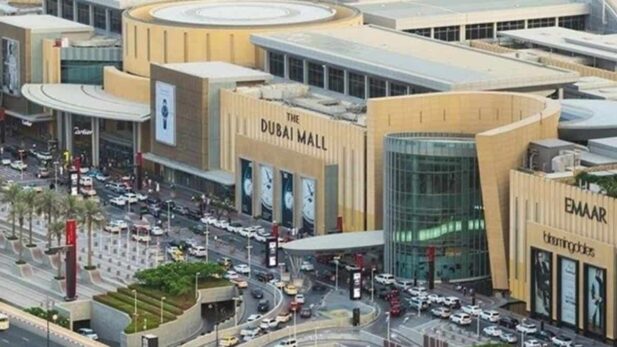

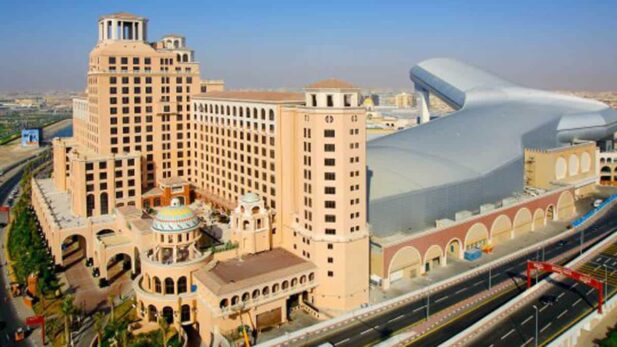

Founded in 2006, Classic Metal Coating has contributed to some of the UAE’s most iconic developments, including Expo 2020, Dubai Metro, Burj Khalifa, Dubai Mall, Atlantis Hotel, and Abu Dhabi International Airport. Our footprint spans across prestigious commercial, hospitality, retail, and luxury residential projects throughout the UAE and GCC. With an ISO accreditation and a reputation for quality, perfection, and promptness, we are proud to be one of the most sought-after metal coating companies in UAE.

What is Electroplating?

Electroplating is the process of applying a thin layer of metal onto a surface using electrical current. This controlled deposition enhances not only the aesthetic appeal of the product but also its functionality and lifespan. In modern industries, electroplating is valued for its ability to create a luxurious finish at a fraction of the cost of solid precious metals—making it ideal for both decorative and functional applications.

This is especially important in areas like metal coating in Sharjah and Dubai, where both visual standards and material resilience are vital for high-end commercial and residential projects.

Are you in search of metal coating in Dubai? Call Us Right Away!

Popular Finishes We Offer:

Gold

Elegant and timeless

Antique Finishes

Aged luxury look

Copper

Classic, antibacterial properties

Nickel

Strong, corrosion-resistant

Brass

Warm, polished finish

Chrome

Mirror-like, high-wear coating

Rustic & Patination

Natural, vintage effect

PVD Coating

Durability, Aesthetics & Performance

Black Nickel

Bold, contemporary elegance

Whether you’re looking for metal coating in Ajman, Sharjah, or sourcing from top-tier metal coating companies in Dubai, Classic Metal Coating is your trusted partner.

Choosing Classic Metal Coating means partnering with a team that values precision, integrity, and long-term success.

- ISO-Certified Processes

- Over 20 Years of Proven Experience

- Wide Range of Finishes & Customizations in metal coating in Sharjah

- Transparent, Reliable, and Sustainable Practices

- Unmatched Quality with Timely Delivery

- Serving All Emirates: Dubai, Sharjah, Ajman, Umm Al Quwain, Ras Al Khaimah, Abu Dhabi, Fujairah

- State-of-the-art equipment and eco-friendly materials

- Strict quality control at every stage

- Expert guidance for designers and contractors

- Competitive pricing without compromising quality

- Flexible batch sizes — from individual custom pieces to large-scale projects

Electroplating is the mechanism by which an electro-deposition is applied to another piece of metal (or to another conductive surface) using an energy current. The deposited metal becomes part of the current product in electroplating through plating/coating.

For electroplating a metal, it needs to generate an electric current with two different metals, an electrolyte solution, two electrodes, and battery or other energy.

Electroplating usually offers a more luxurious finish to cheaper metals and adds certain properties such as anti-corrosion and anti-rust.

There are many factors why a leading surface of metal should be coated. In the case of silver– and gold-plated items or silverware or decorative items, the appearance and value of these objects are usually enhanced. Chromium-plated items enhance the look and wear of artifacts. Electroplating can also be performed to increase an object’s thickness.

- Enhanced Visual Appeal : Elevate your products and surfaces with luxurious, decorative finishes that match modern design trends.

- Corrosion & Rust Protection : Electroplated coatings act as a barrier, protecting base metals from moisture, air, and chemical reactions—ideal for UAE’s humid climate.

- Improved Durability : Thicker coatings increase resistance to scratches, shocks, and environmental stress, making it a long-term investment.

- Reduced Friction : Particularly with nickel coatings, parts function smoother with reduced wear and tear—important for industrial and electrical components.

- Better Adhesion & Finish : Copper undercoats ensure even surface plating and are ideal when multiple layers or materials are involved.

- Thickness Customization : Electroplating allows you to control coating thickness, essential for specific mechanical or visual requirements.

We offer expert electroplating in Sharjah, Abu Dhabi, Dubai, and across the UAE, using advanced electro-deposition technology to apply premium finishes such as:

- Gold and Silver Plating: A luxurious touch with antibacterial properties.

- Nickel and Chrome Plating: Reflective, corrosion-resistant, and durable.

- Antique Finishes: Adds a vintage, aged aesthetic ideal for decorative elements.

- Copper, Brass, Patina, and Black Nickel Finishes: Custom options for both classic and contemporary design needs.

Electroplating not only enhances visual appeal but also provides anti-corrosion, wear resistance, increased thickness, and friction reduction—ideal for high-traffic installations and long-term usage.

Whether you’re working with interior fixtures, signage, hotel décor, mall interiors, or industrial frames, we provide custom metal coating in Ajman, tailored to your exact specifications. Our expert team ensures every project is handled with attention to detail, surface integrity, and environmental sustainability.

Discover the Power of Premium Metal Coating!

As one of the most experienced metal coating companies in Dubai and Sharjah, we cater to a wide range of industries, including:

- Retail & Luxury Boutiques

- Hospitality & Hotels

- Airports, Metro, and Government Projects

- Interior Fit-Outs & Commercial Spaces

- Jewellery and Decorative Fixtures

- Architectural & Cladding Components

- Custom Villas and Residences

OUR PRESTIGIOUS PROJECTS

- Antique

- Brass

- Copper

- Gold

- Silver

- Nickel

- Chromium

- Black Nickel

- Rustic

- Patination