There is an increased demand for antique metal plating these days to enhance the beauty of decorative items mostly. Antique coatings looks good at brass and copper as there are different variations for blues, greens and bronzes. This type of metal coating provides an authentic aged appearance for products with many color options, lacquering stability and decorative factors.

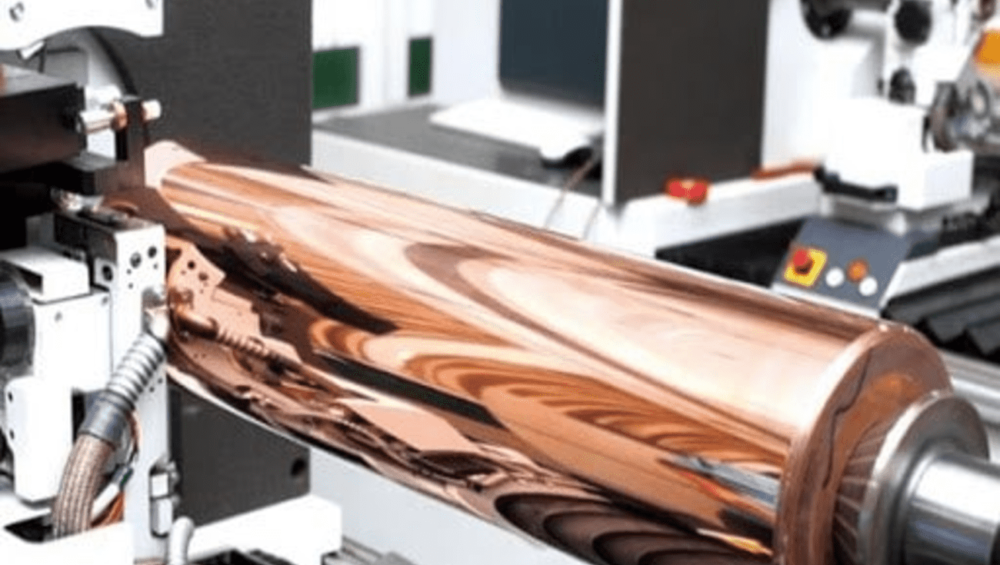

Antique coating is done by using a selenium based solution to which the specific component is immersed. The solution mix varies, depending up on the type of the oxidizing material and the factors of temperature, time and concentration of the solution contributes to antique finishing. For a better service, finding an experienced metal coating company is essential. Find our prime antique finishes plating in UAE for a quality yet affordable service. We will discuss about some important concepts about antique finishing before you do or decide to hire.

What to expect from Antique coating?

This is really your choice to make your décor fascinating with an authentic aged look. It is something done by manipulating the paint finish, allowing a range of beautiful layouts to enhance every type of design. The shade scheme you select creates different looks for the antique plated surface and its worth of doing to prevent corrosion and adds personality to your products. Find a reliable service among the many metal coating companies in Dubai to get the right direction in Antique coating for your project for an efficient planning.

It is mostly a Decorative plating

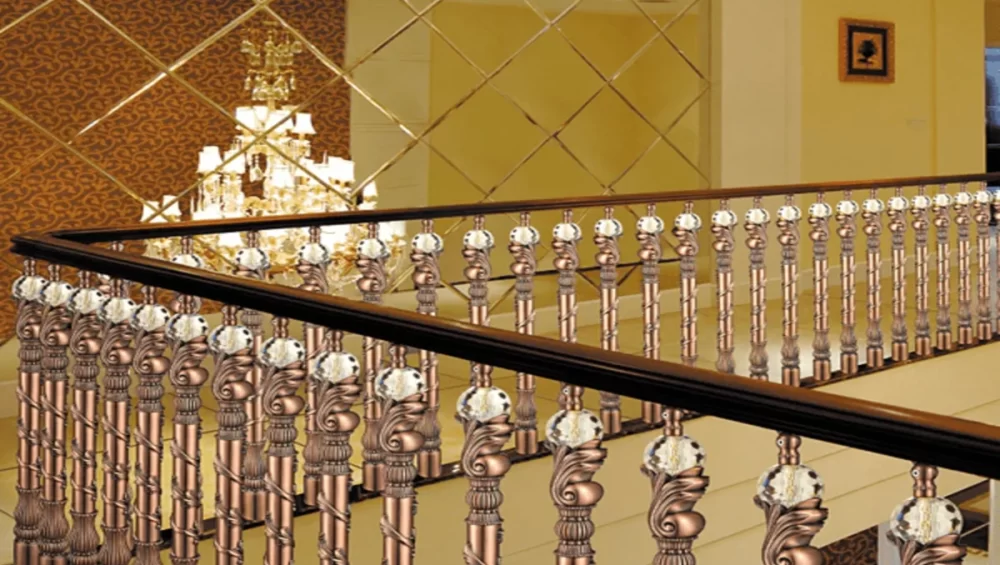

Having done with an electroplating process of antique coating, it really makes the products beautiful to get a unique aged look. So it can be regarded as a decorative plating process whereby a thin layer of brass, chrome, nickel or copper is deposited on the selected component which really brings out the texture of the particular décor well at any circumstances. The process introduces a dark oxide layer over the surface of the bright plated alloy and creates a visual depth on all those exposed parts of the product to quickly analyze it. A layer of lacquer is applied after plating to avoid tarnishing and to preserve the finish.

Antique Brass, copper, bronze Plating

Antique electroplating has wide application in automobile industries, interior architecture, construction materials and many more. The antique electroplating process is the newest trend in the industry presently and can be used in various metals mainly stainless steel, brass aluminum, and to provide an authentic look and long term protection. Classic metal coating LLC provided the best antique metal coating in dubai, for multiple clients and industries such as hotel interiors, airlines, palace interiors and malls where stainless steel needs a transformation to get an antique and aesthetic appearance. Get the grand look of antique finish for every metal structure you prefer at affordable rates only at classic metal LLC, Dubai.

Choose the professionals in the field

Finding an expert service providing the complete line of antiquing and oxidizing process is important for various projects. For architectural projects, the plating process gives a rusty brown- greens or brown- oranges often or for decors, a range of browns and blacks can result providing a weathered look. For silver products, that can be pleasing blues and purples which gives an aged appearance. Making your valuables perfect with such antique touches can be done fast and fine with electroplating. The process is delivered by many electroplating companies in Dubai, from where you can book in advance, providing your material specification and needs. Classic metal coating is one of a kind in Antique finishes plating in UAE, doing professional service in the sector over a decade of experience.

What we promise in Antique Metal Coating service

Classic metal Coating L.L.C have been doing their prestigious service in metal coating with 17 years of experience in the UAE and the Gulf regions. We do admirable antique finishes plating in UAE for every type of projects and services with the aim of creating an authentic finish to the components, adding a unique character and protection to the surfaces. We are one of the leading electroplating companies in Dubai, specializing in Gold plating, Silver plating,, Brass and antique finishing, copper, Nickel & chrome plating, rustic and Blacken coating. We promise a transparent, reliable and responsible business solution in metal coating service, contributing our professionalism & experience to create high standards in the industry.