Electroplating, which involves applying an electrical current to a surface to deposit a layer of metal, has transformed numerous businesses and daily items. Electroplating has developed significantly over time, making it possible to create items that are both long-lasting and attractive to the eye. This blog will examine the fascinating development of electroplating, from its primitive origins to the state-of-the-art methods used today.

Origins of Electroplating:

The invention of electroplating dates back to the early 19th century, when Italian chemist Luigi Brugnatelli used an electrochemical method to effectively cover silver objects with a thin layer of gold. But George Elkington, an Englishman, is frequently given the credit for developing commercial electroplating. The first practical electroplating method was invented by Elkington and his cousin Henry in 1840, opening the door for its industrial use.

Advancements in Electroplating Techniques:

As electroplating in UAE became more common, scientists and engineers worked to enhance the method and broaden its uses. One important breakthrough was the creation of more effective power sources, like rectifiers and dynamo-electric machines. These developments made it possible to provide electroplating with a steady and consistent power source, which produced metal coatings of better calibre and greater uniformity.

Introduction of New Metals and Alloys:

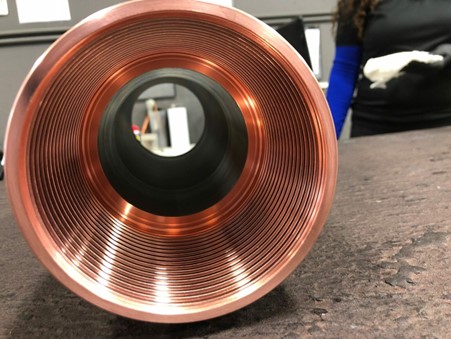

Electroplating methods have improved over time to work with a wider variety of metals and alloys. Initially, the main metals used for electroplating were copper, silver, and gold. However, technological developments made it possible for metals like nickel, chromium, and tin to be deposited, improving both corrosion resistance and aesthetic features. Additionally, new alloys that found use in a variety of industries, including bronze, brass, and stainless steel, were developed in large part thanks to electroplating.

Industrial Applications and Advantages:

The automobile, aerospace, electronics, and jewellery industries were among the first to adopt electroplating. Electroplating served the automotive sector in particular by being used for decorative chrome plating, which gave car parts a bright and corrosion-resistant finish. In the production of printed circuit boards for electronics, electroplating was essential because it allowed for accurate deposition of copper traces and ensured dependable electrical connections.

Environmental Considerations and Innovations:

The obstacles associated with waste disposal and the use of hazardous chemicals in electroplating increased as society grew more conscious of environmental issues. Significant attempts were made, nonetheless, to resolve these problems.

Future Prospects:

With continued study and technological developments, electroplating in UAE appears to have a bright future. Electroplating is currently experiencing a significant surge in popularity for decorative purposes, particularly in hotels and shopping malls. This innovative technique not only provides a visually appealing aesthetic but also ensures durability, surpassing the longevity of traditional painting methods. As a result, electroplating has become the preferred choice among interior designers seeking to enhance the overall appearance of spaces.

Conclusion:

Significant developments have been made in electroplating over the years, increasing its capabilities and uses. Electroplating in Dubai has influenced several industries and changed commonplace items from its humble beginnings to its modern state-of-the-art processes. The future of electroplating has a tremendous deal of opportunity for additional innovation, sustainability, and versatility in order to fulfil the demands of a fast-changing world.