Metal coating in Sharjah and UAE is done with different options. In the industrial world, machines play the most important role and are made up of a large number of components. The metallic components can’t operate well without some coating for protecting the metal surface or reducing friction. There are many types of metals and the different supply of applications for coatings available. The experts in the business of electroplating in UAE know the technical ways for coating the metal and work professionally with the metal coating companies in Dubai.

Generally, there are different types of coatings available on metals to change their properties or add to their grace. These coating types are:

Plastic coating: Plastic Coating comes in different sizes and shapes. There are many types of plastic coatings available for metallic parts ranging from fluoropolymers to ETFE under different brand names. The non-stick coating is done on the cooking material with the name Teflon that is a trademark in the cookware appliances.

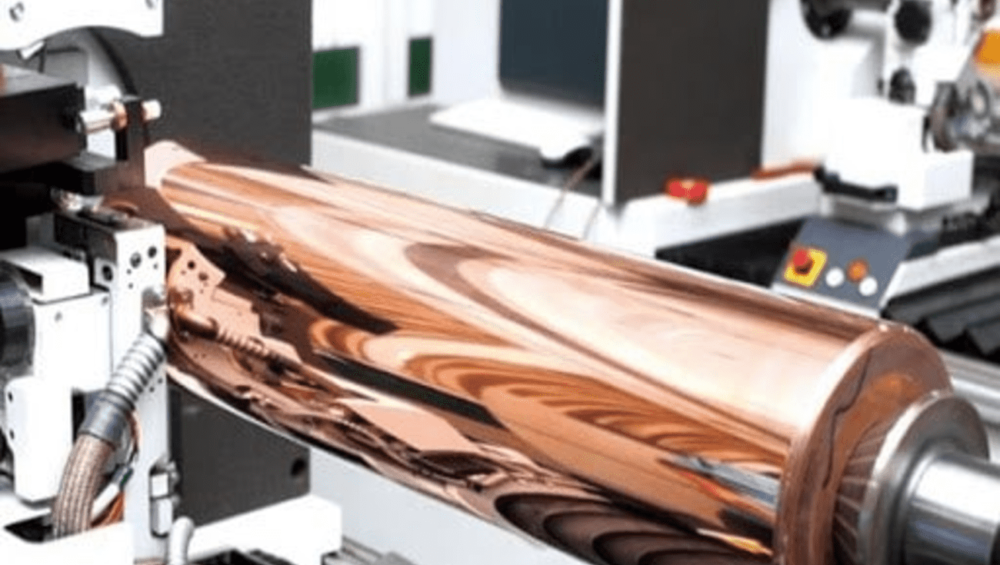

Metal: At times, a part of the metal is used to make a part and the other metal provides the right properties for protecting the first metal. The metal coating changes over time with the addition of products, such as NitroCoat. In this way, electroplating in Dubai and UAE is done for various metals for coating and applied using the chemicals in the advanced application process. Whether you need extra lubrication, aesthetic properties, or a protective layer over the metal body. Electroplating Companies in Dubai work professionally for different modes of electroplating to provide an extra coating on metals.

Paint: Painting metal is mainly used for its protection from corrosion. In general life, we see that a car is painted to keep the body protected from rusting. Paint is a protector of metal from any corrosive and rusting actions.

Polymer Coating: The whole industry is filled with polymers providing the best coating for metals. The list of polymers is very long. Some plastic products are also termed polymers. This is done to prohibit the exposure of metal to the outside environment and saves it from the impact of any unwanted reaction.

There are many coating applications and you can’t understand the best for your use unless you consult an expert. The type of coating on the working metal parts is one of the most important components for your selection. You must make the choice based on the machine temperatures, parts coming into contact, and other important details. The experts working for electroplating companies in Dubai can give the most reliable suggestions for the most important components that are workable for your application.

Conclusion:

Classic Metals LLC provides the different types of metal coating in Sharjah and other parts of the UAE. They help you to figure out the best coating for your needs. They offer different application technologies including high or low volume coatings on the equipment based on its obtainable properties. The company works for electroplating in UAE with expert guidance and sophisticated devices for coating the metal bases.

Classic Metals LLC follows uncompromising standards and is among the top metal coating companies in Dubai. They provide the best and professional services at affordable prices. Whether it is a customized single coating or bulk projects, the company works for delivering a quick turnaround for all their projects. They’ve worked on multiple projects in UAE and fetched out the most responsible results for electroplating in UAE. The experts have specialized in gold, silver, and copper plating in UAE. You can contact the experts and share your requirements to get the best guidance for your metal coating needs.